The rise of electric vehicles has become one of the most important shifts in global transportation. As governments encourage cleaner mobility and consumers become more environmentally conscious, the demand for efficient and reliable EVs continues to grow. While batteries and electronics often receive the most attention, mechanical engineering plays a central role in making EVs safe, efficient and ready for mass adoption. Students pursuing a B.Tech in Mechanical Engineering from the best btech college for mechanical engineering in Jaipur today are stepping into a field filled with innovation and new possibilities. Their knowledge, analytical skills and creativity are helping the electric vehicle revolution gain momentum in many meaningful ways.

Mechanical engineering is built on understanding how machines and structures behave. This understanding becomes even more important in electric vehicles, which require new design approaches and problem solving methods. From body design and thermal systems to drivetrain development and aerodynamics, mechanical engineers are deeply involved in shaping the EV landscape. The following sections explore how each part of the mechanical engineering curriculum contributes to the growth of the EV sector.

1. Designing Efficient and Lightweight Vehicle Structures

Lightweight design is essential in electric vehicles because the battery pack adds considerable weight. To increase the driving range, engineers must compensate by reducing weight in other parts of the vehicle. Mechanical engineers use their knowledge of materials, structural analysis and mechanics to design strong yet lightweight structures. During their B.Tech studies, they learn how different materials behave under stress and how to analyze structures for strength and safety. These skills help them create chassis designs, vehicle frames and body structures that support the weight of the battery while keeping the vehicle efficient. Their ability to combine material science with structural engineering helps EV manufacturers increase range without compromising durability or passenger safety.

2. Innovating Better Thermal Management Systems

Thermal management becomes especially important in electric vehicles because batteries, power electronics and motors generate heat during operation. If the heat is not controlled, it can reduce performance, increase charging time and shorten the lifespan of the components. Mechanical engineers apply principles of thermodynamics, fluid mechanics and heat transfer to design effective cooling systems. They work on liquid cooling loops, improved airflow, heat exchangers and insulation materials that maintain ideal temperatures. These innovations ensure that EVs perform consistently in different climates and driving conditions. With better thermal management, batteries remain safe, motors work more efficiently and electronic components stay protected.

3. Improving Electric Powertrains and Drivetrain Components

Although electric vehicles do not use traditional engines, they still require well designed mechanical systems to transmit power smoothly and efficiently. Mechanical engineers work on gear reduction mechanisms, shafts, bearings, motor housings and structural components of the motor assembly. Courses in dynamics, machine design and mechanics of materials help students understand how these systems work under different loads and speeds. They also contribute to the development of regenerative braking systems, which help increase energy efficiency by converting braking force into stored electrical energy. With their deep understanding of mechanical motion and material behavior, mechanical engineers ensure that EV powertrains perform reliably and remain durable over long periods of use.

4. Enhancing Battery Pack Design and Safety

The battery pack is one of the most important parts of an electric vehicle. While electrical and chemical engineers focus on the battery cells, mechanical engineers handle the structural design and safety of the battery pack. They design enclosures that protect battery cells from vibration, shock and impact. They also conduct crash simulations and safety tests to ensure that the battery compartment remains secure during an accident. Through their training, they learn how to integrate the battery pack into the vehicle structure without affecting balance or stability. Safe battery pack design increases the lifespan of the battery and protects the vehicle occupants.

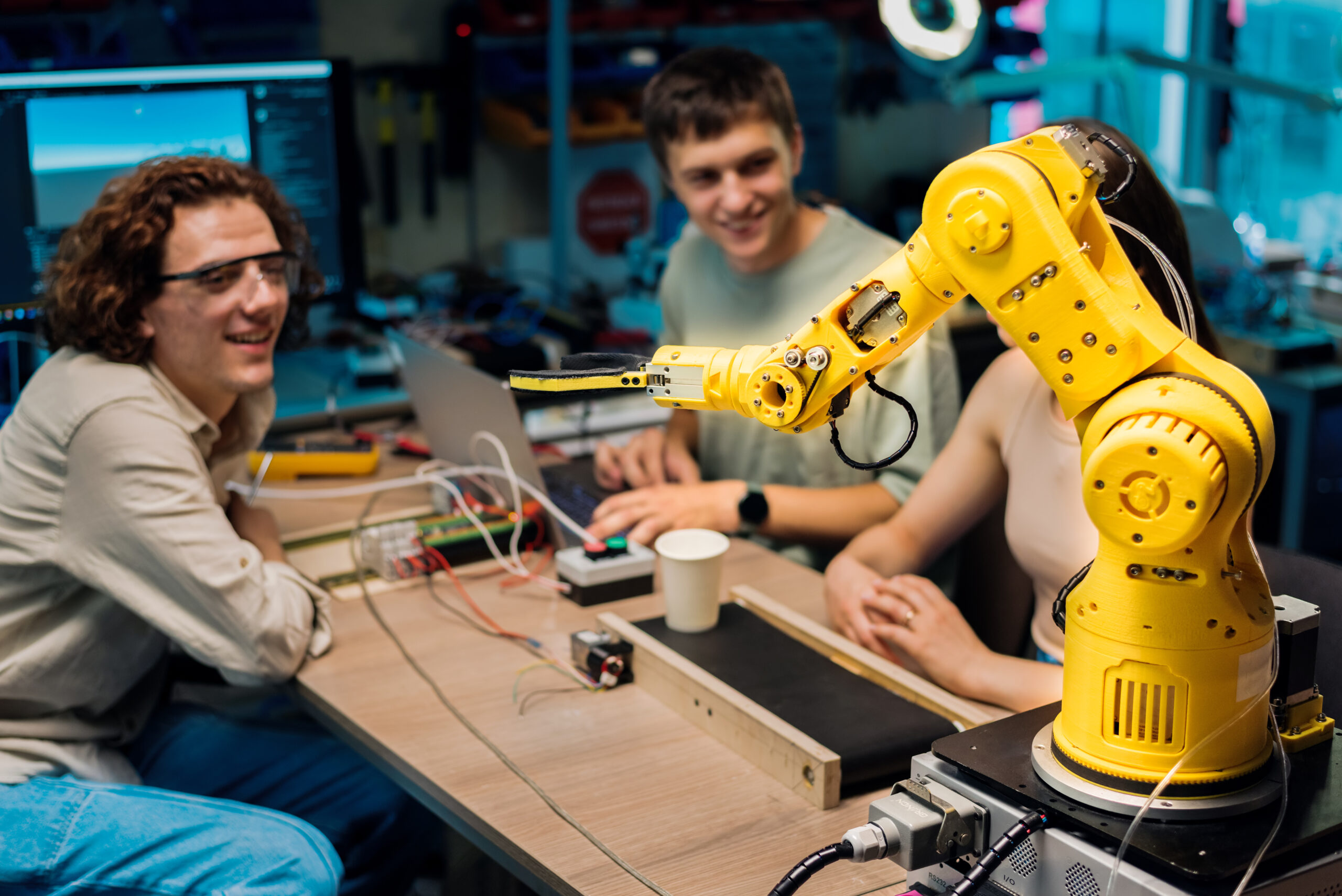

5. Supporting Manufacturing and Automation of EV Production

EV production involves advanced manufacturing techniques, automation systems and precision engineering. Mechanical engineers study manufacturing processes, industrial engineering principles and production planning. These skills allow them to design efficient assembly lines that improve productivity and minimize waste. They help develop robotic welding systems, assembly fixtures, joining techniques and quality control methods that ensure consistent and reliable production. Their understanding of manufacturing technology helps reduce production costs and increases output. As the EV market grows rapidly, companies need skilled mechanical engineers who can modernize factories and support large scale manufacturing.

6. Advancing Aerodynamics for Better Range

The shape of an electric vehicle greatly influences its energy consumption. Since EVs rely entirely on stored electrical energy, reducing air resistance is essential for extending driving range. Mechanical engineers analyze how air flows around the vehicle using computational simulations and wind tunnel testing. They study concepts like drag, lift and airflow patterns taught during their B.Tech program. These concepts help them modify vehicle shapes to make them more aerodynamic. Even small changes can provide noticeable improvements in range, especially at higher speeds. By working on aerodynamics, mechanical engineers help EVs travel farther without needing larger batteries.

7. Building Charging Infrastructure and Energy Systems

Mechanical engineering also supports the development of EV charging infrastructure. Fast charging stations generate large amounts of heat, and mechanical engineers design the cooling systems that keep them safe and functional. They also work on the mechanical design of charging connectors, housing structures and battery swapping stations. Skills gained during their studies allow them to ensure that the entire ecosystem around electric vehicles is structurally sound and user friendly. Without efficient and safe charging systems, the EV revolution would not be able to progress smoothly. Mechanical engineers help ensure that charging stations and related systems meet safety standards and withstand long term use.

8. Researching New Materials and Sustainable Solutions

The EV industry constantly explores new materials that offer better strength, reduced weight and improved sustainability. Mechanical engineers play a key role in researching and testing materials like aluminum alloys, composites and high strength steels. They study how these materials respond to heat, pressure, vibration and long term use. This research helps manufacturers select the right materials for different parts of the vehicle. As sustainability becomes more important, mechanical engineers also explore materials that can be reused or recycled at the end of the vehicle’s life. Their research supports an eco-friendly approach to vehicle design and manufacturing.

Conclusion

The electric vehicle revolution is not driven by one discipline alone. It is supported by a combination of innovation in mechanical engineering, electronics, software and material science. A B.Tech in Mechanical Engineering from the top college for mechanical engineering in jaipur provides students with the knowledge and practical skills needed to contribute to EV design, safety, performance and production. From lightweight structures to aerodynamics, from powertrain components to thermal systems, mechanical engineers play a crucial role in shaping the future of sustainable transportation. As the demand for electric vehicles continues to rise, mechanical engineers will remain at the forefront of this transformation, using their expertise to create cleaner, safer and more efficient mobility solutions for the world.