The field of robotics is a testament to the remarkable synergy of engineering disciplines at the best private college for mechanical engineering in Jaipur. It is where the mechanical world meets the electrical that creates machines that can perform complex tasks with precision. From industrial robots on assembly lines to humanoid robots exploring uncharted terrains, the collaboration between mechanical and electrical engineers is the cornerstone of every innovation in robotics. But how do these professionals work together? Let’s dive into the fascinating world of interdisciplinary engineering to understand their collaboration.

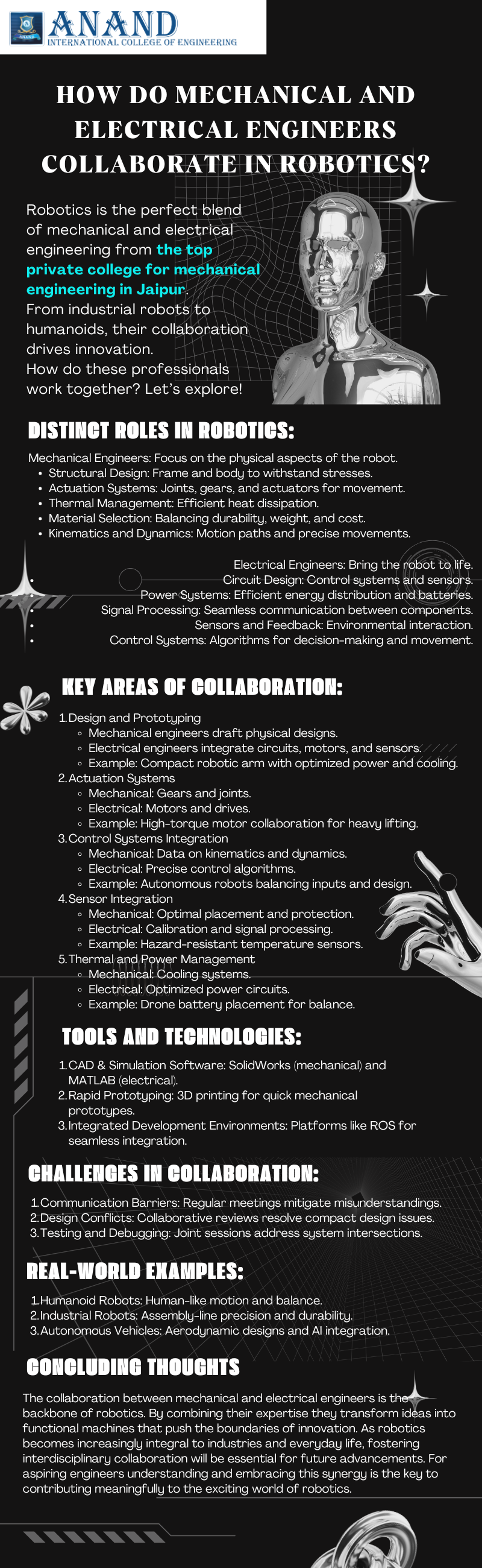

The Distinct Roles of Mechanical and Electrical Engineers in Robotics

Before we explore the collaboration it is essential to understand the specific roles of mechanical and electrical engineers in a robotics project.

Mechanical Engineers

Mechanical engineers focus on the physical aspects of a robot. Their responsibilities include:

- Structural Design: Developing the frame and body of the robot to ensure it can withstand operational stresses.

- Actuation Systems: Designing joints, gears and actuators for movement and functionality.

- Thermal Management: Ensuring the robot can dissipate heat effectively during operation.

- Material Selection: Choosing materials that balance durability, weight and cost.

- Kinematics and Dynamics: Calculating motion paths and forces to achieve precise movements.

Electrical Engineers

Electrical engineers bring the robot to life by focusing on its electronic and power systems. Their responsibilities include:

- Circuit Design: Creating circuits for control systems and sensors.

- Power Systems: Designing efficient power distribution and battery systems.

- Signal Processing: Ensuring seamless communication between components.

- Sensors and Feedback: Integrating sensors for environmental interaction and feedback.

- Control Systems: Developing algorithms and hardware for decision-making and movement control.

As each discipline has its distinct responsibilities the overlap in their work fosters collaboration.

Key Areas of Collaboration

1. Design and Prototyping

Robotics projects begin with a design phase where mechanical and electrical engineers collaborate to outline the robot’s capabilities and structure. Mechanical engineers draft the physical design while electrical engineers ensure that the proposed design can house necessary components like circuits, motors and sensors.

For example if a mechanical engineer designs a compact robotic arm, an electrical engineer ensures that the power supply and control units can fit within the designated space without overheating.

2. Actuation Systems

Actuators are the heart of a robot’s movement that convert electrical energy into mechanical motion. Mechanical engineers design the gears, joints and linkages while electrical engineers select and integrate the motors and drive systems.

The collaboration here is critical. For instance a mechanical engineer might propose a high-torque motor for heavy lifting. The electrical engineer then evaluates the power requirements and ensures the motor’s compatibility with the power system.

3. Control Systems Integration

Control systems are the brain of a robot which translates commands into actions. Mechanical engineers provide data on the robot’s kinematics and dynamics which electrical engineers use to design precise control algorithms.

In autonomous robots this collaboration becomes even more intricate. Electrical engineers develop software to process sensor inputs while mechanical engineers ensure the physical design can respond to those commands effectively.

4. Sensor Integration

Sensors play a pivotal role in enabling robots to perceive their environment. Mechanical engineers determine optimal sensor placement to ensure accurate readings without compromising the robot’s structural integrity. Electrical engineers handle the wiring, calibration and signal processing of these sensors.

For instance in a robot designed for hazardous environments mechanical engineers might design a protective casing for a temperature sensor. Simultaneously electrical engineers ensure the sensor’s data is transmitted accurately to the control unit.

5. Thermal and Power Management

Heat dissipation and power distribution are shared concerns in robotics. Mechanical engineers design cooling systems like heatsinks and airflow channels while electrical engineers optimize power circuits to minimize energy loss.

In high-performance robots such as drones, this collaboration is crucial. Electrical engineers might design a high-capacity battery while mechanical engineers ensure the battery’s placement does not affect the robot’s center of gravity.

Tools and Technologies Enabling Collaboration

- CAD and Simulation Software

- Mechanical engineers use CAD software like SolidWorks for 3D modeling.

- Electrical engineers use tools like MATLAB and Simulink for circuit simulation.

- Integration of these tools ensures that both teams can visualize and test their designs collaboratively.

- Rapid Prototyping

- Technologies like 3D printing allow mechanical engineers to quickly create prototypes.

- These prototypes are then equipped with electrical components for testing.

- Integrated Development Environments (IDEs)

- Platforms like ROS (Robot Operating System) facilitate seamless integration of mechanical and electrical components.

Challenges in Collaboration

Collaboration between mechanical and electrical engineers is not without challenges despite the benefits :

- Communication Barriers

- Different terminologies and approaches can lead to misunderstandings.

- Regular interdisciplinary meetings can mitigate this issue.

- Design Conflicts

- A compact design by mechanical engineers might not accommodate the electrical components.

- Collaborative design reviews can help resolve such conflicts early.

- Testing and Debugging

- Issues often arise at the intersection of mechanical and electrical systems.

- Joint testing sessions can identify and address these issues effectively.

Real-World Examples of Collaboration

- Humanoid Robots

- Mechanical engineers design joints mimicking human motion while electrical engineers develop algorithms for balance and navigation in humanoid robots.

- Industrial Robots

- In assembly-line robots, mechanical engineers focus on the arm’s precision and durability while electrical engineers ensure the motors and controllers can handle repetitive tasks efficiently.

- Autonomous Vehicles

- Mechanical engineers design vehicle frames optimized for aerodynamics, while electrical engineers integrate sensors and AI systems for navigation.

The Future of Collaboration in Robotics

The collaboration between mechanical and electrical engineers will only deepen as robotics continues to evolve. Emerging technologies like soft robotics, AI and advanced sensors demand even more seamless integration of physical and electronic systems.

For instance in soft robotics the mechanical design focuses on flexibility and adaptability while electrical engineers develop lightweight power systems and neural networks for control.

Conclusion

The collaboration between mechanical and electrical engineers is the backbone of robotics. By combining their expertise they transform ideas into functional machines that push the boundaries of innovation. As robotics becomes increasingly integral to industries and everyday life, fostering interdisciplinary collaboration will be essential for future advancements. For aspiring engineers from the top private college for electrical engineering in Jaipur, understanding and embracing this synergy is the key to contributing meaningfully to the exciting world of robotics.