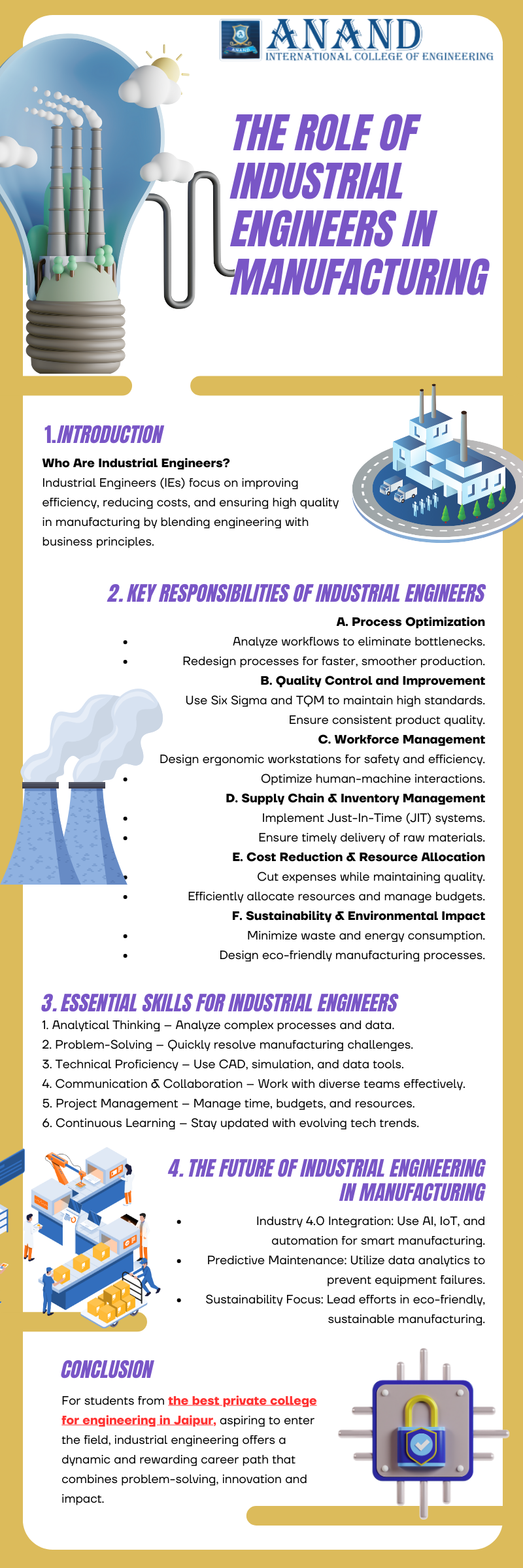

In today’s fast-paced world manufacturing industries are constantly seeking ways to improve efficiency, reduce costs and maintain high-quality standards. Here the role of Industrial Engineers are important as they are professionals dedicated to making processes smoother, faster and more cost-effective.

Industrial engineers (IEs) play a pivotal role in the manufacturing sector, blending engineering principles with business acumen to streamline production, enhance productivity, and ensure that every component of the manufacturing process works in harmony.

In this article, we’ll explore the vital role industrial engineers play in manufacturing, their key responsibilities, essential skills and the impact they have on shaping the future of the industry.

What is Industrial Engineering?

Industrial engineering is a branch of engineering that focuses on optimizing complex systems and processes. It combines knowledge from multiple disciplines such as engineering from the top college for engineering in Jaipur, mathematics, business, and human sciences. Unlike other engineering branches that focus solely on machinery or infrastructure, industrial engineering is centered on improving how things work, like designing efficient workstations, reducing waste or managing supply chains.

In manufacturing, industrial engineers act as the bridge between management and operations, ensuring that systems are not only technically sound but also economically viable.

Key Responsibilities of Industrial Engineers in Manufacturing

Industrial engineers are responsible for many roles in the manufacturing environment. Their responsibilities can range from designing production layouts to analyzing workflows. Here are some of their primary roles:

1. Process Optimization

The main focus here is to make processes more efficient. Industrial engineers analyze production processes to identify bottlenecks, waste and inefficiencies. They then redesign these processes to improve speed, reduce errors and lower costs.

For instance in an automotive plant, an industrial engineer might streamline assembly line operations to reduce the time it takes to produce each car and save both time and resources.

2. Quality Control and Improvement

Industrial engineers are also heavily involved in quality control. They develop systems to ensure that products meet or exceed quality standards. Industrial engineers help manufacturers produce high-quality products consistently by implementing statistical tools like Six Sigma or Total Quality Management (TQM),

3. Workforce Management

A significant part of industrial engineering involves optimizing human labor. IEs study the interactions between workers and machines to design ergonomic workstations, improve worker productivity and ensure safety. They focus on creating environments where workers can perform efficiently without compromising their health or well-being.

4. Supply Chain and Inventory Management

Efficient supply chain management is crucial in manufacturing. Industrial engineers ensure that raw materials are delivered on time, inventory levels are optimized and production schedules are maintained. They use tools like Just-In-Time (JIT) inventory systems to minimize waste and reduce holding costs.

5. Cost Reduction and Resource Allocation

The engineers are tasked with reducing manufacturing costs without compromising on quality. They analyze cost structures, identify areas where expenses can be cut and allocate resources more efficiently. By doing so they help companies remain competitive in a global market.

6. Sustainability and Environmental Impact

In an era where sustainability is paramount industrial engineers play a key role in reducing the environmental impact of manufacturing processes. They design systems that minimize waste, reduce energy consumption and promote the use of sustainable materials that align manufacturing practices with environmental goals.

Essential Skills for Industrial Engineers in Manufacturing

To excel in their roles, industrial engineers need a blend of technical and soft skills. Here are some of the key competencies:

1. Analytical Thinking

They must be able to analyze complex processes, identify problems and devise innovative solutions as they rely heavily on data analysis and statistical methods to drive improvements.

2. Problem-Solving Abilities

Manufacturing environments are dynamic with challenges arising frequently. Industrial engineers need strong problem-solving skills to address issues quickly and effectively.

3. Technical Proficiency

A solid understanding of engineering principles, manufacturing processes, and tools like Computer-Aided Design (CAD) and simulation software is essential.

4. Communication and Collaboration

Industrial engineers often work in multidisciplinary teams as they interact with managers, operators and suppliers. Strong communication skills are vital to convey complex ideas clearly and collaborate effectively.

5. Project Management

Managing time, resources and budgets is a crucial part of their role. Project management skills help them ensure that improvements are implemented on schedule and within budget.

6. Adaptability and Continuous Learning

Manufacturing technologies and methodologies are constantly evolving, thus, industrial engineers must stay up-to-date with the latest trends, tools, and best practices to remain effective.

Impact of Industrial Engineers on the Future of Manufacturing

Industrial engineers are at the forefront of driving innovation in manufacturing. As industries move towards smart manufacturing and Industry 4.0, the role of IEs is expanding. They are integrating advanced technologies such as automation, artificial intelligence (AI), and the Internet of Things (IoT) to create intelligent production systems.

For example, industrial engineers are using data analytics and AI to predict equipment failures before they happen, reducing downtime and maintenance costs. They are also leveraging IoT to track production in real-time, enhancing visibility and control over manufacturing processes.

Moreover, with the growing emphasis on sustainability, industrial engineers are leading efforts to design eco-friendly manufacturing processes that reduce carbon footprints and promote circular economies.

Conclusion

Industrial engineers are indispensable to the manufacturing sector. Their ability to blend technical expertise with business insight allows them to optimize processes, enhance quality, and drive cost savings. As manufacturing evolves with new technologies and sustainability goals, the role of industrial engineers will only become more critical.

For students from the best private mechanical college for engineering in Jaipur, aspiring to enter the field, industrial engineering offers a dynamic and rewarding career path that combines problem-solving, innovation and impact. Whether it’s designing more efficient factories, improving product quality or developing sustainable solutions, industrial engineers are shaping the future of manufacturing.